Global Nuclear Power Safety Center

Nuclear power is picking up steam in many countries because it does not emit greenhouse gases and it is able to produce power on a consistent, reliable basis.

To meet the pressing needs for technical support in the U.S. and global nuclear power market, the GNPS Center, consisting of groups of faculty who specialize in the various topic areas of interest to nuclear safety, including nuclear fuel and materials, advanced instrumentation and control, innovative cooling enhancement, experimental support, system code development, and education and training, was established in June 2016, with a kick-off meeting held on June 23, 2016. The event was attended by representatives from the U.S. Nuclear Regulatory Commission (NRC), the State Nuclear Power Technology Research & Development Center (SNPTRD), and the Shanghai Nuclear Engineering Research & Design Institute (SNERDI), who toured various research facilities at Penn State. The Center brings together experts from across the University in an effort to enhance the safety performance of existing nuclear power plants and promote safety design features of future advanced reactors in the United States and around the globe.

Mission

The GNPS Center aims to advance the base technology in nuclear power (NP) safety and developing marketable research tools and products that are useful for:

- promoting the safe operation and performance of existing nuclear power plants,

- providing essential information in the design and development of inherently safe, future advanced high-power reactors, and

- educating and training professional engineers, practitioners, designers, and researchers working in the NP safety area as well as students aiming at becoming future industry and academic leaders in the global NP safety area. The various research, education, and training activities being conducted at the GNPS Center, along with the marketable research tools and products being developed will provide the much needed technical support to the U.S., as well as international (global) nuclear power designers and vendors. The research products of the GNPS Center should also help improve the capability of reactor safety analysis for licensing purposes in the U.S., as well as in other countries.

Challenges and Opportunities

Nuclear power is a carbon-neutral, green-energy resource capable of meeting energy, environmental, and national security needs. Today, nuclear energy represents the single largest source of energy, accounting for nearly 20 percent of the electricity generated in the U.S. With approximately 440 commercial reactors operating in 30 countries — and 300 more valued at $1.6 trillion projected worldwide over the next 15 years — nuclear power is surely a major energy source and economic engine for many decades to come. In addition to providing clean and reliable electricity, nuclear energy will continue to play a key role in supporting energy security, creating jobs, and providing export opportunities.

The global nature of nuclear power, both in its benefits and challenges, is why robust international collaboration is crucial and why the international collaboration opens a window of opportunity for the Nuclear Engineering Program (NEP) at Penn State as a key element of its overall mission and programmatic activities. While nuclear power continues to develop in the U.S. and will continue to be the major focus of NEP it can be combined with strong international participation and collaboration. Most new nuclear power plants are being constructed or planned abroad and in some cases in countries where nuclear power expertise is missing or in a developing stage. As a result, there are pressing needs for technical support in the global nuclear power market that the GNPS Center can help supply. The timing for formation of the GNPS Center could not be better. Nuclear power is developing in many countries at an increasing speed that calls for accelerating research and education in the NP safety areas with many opportunities for funding.

It should be mentioned that U.S. companies are currently building nuclear power reactors abroad. Westinghouse in particular is building AP1000 units in China and is bidding to build AP1000 in Brazil and Bulgaria. Other countries, such as the United Arab Emirates, have plans for building several reactors over the next decade. Many of their scientific personnel are being trained at Penn State and opportunities exist to expand education and research collaboration. There is also a trend for reactor vendors to build higher and higher power reactors. South Korea, for example, is currently building APR1400 units whereas China is building CAP1400 units. Facing the increasing severity of air pollution problems, China has recently committed to build CAP1700, the highest-power PWR ever attempted by mankind. If successful and proven to be safe and highly cost effective, other countries including the U.S., Europe, South Africa, and Middle East may also attempt to build higher-power reactors.

As the power level of future advanced reactors increases, from 1000 MWe to 1400 MWe and now to 1700 MWe, however, the available surface area for cooling does not increase proportionally, resulting in considerably higher power densities and heat fluxes. To assure adequate cooling under design basis accident (DBA) as well as beyond design basis accident (BDBA) conditions, innovative cooling enhancement (ICE) techniques are needed to meet these high-power-density high-heat-flux demands. Until viable ICE technologies become available and are fully acceptable to NP vendors and regulators worldwide, innovative cooling enhancement would remain one of the critical technical challenges for further development of high-power nuclear reactors in years to come.

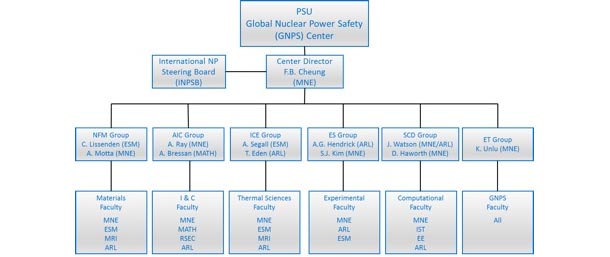

Organization

The GNPS Center, currently housed in Reber Building, forms a strong partnership with the Penn State Applied Research Laboratory (ARL) as well as other units at Penn State, including in particular the Radiation Science and Engineering Center and Materials Research Institute. The organizational structure of the GNPS Center is depicted below. Dr. F. Bill Cheung is the founding Director of the Center whereas Drs. Cliff Lissenden, Arthur Motta, Asok Ray, Albert Segall, Timothy Eden, Angus Hendrick, Seungjin Kim, Daniel Haworth, and Justin Watson are the leaders of the NFM, AIC, ICE, ES and SCD Groups, respectively. Dr. Kenan Ünlü who is well verse in NP education and training will lead the ET Group.

To meet the pressing needs for technical support in the U.S. and global nuclear power market, the GNPS Center involving the participation of multi-college faculty and research staff at Penn State was officially established in June 2016. The GNPS Center focuses on conducting state-of-the-art research, education and training activities in the area of domestic and international (global) nuclear power by advancing the base technology in nuclear power safety and developing marketable research tools and products.

To secure long-term, sustainable revenue for the Center, marketable research and educational tools and products are being developed at the Center. To facilitate the development of these tools and products, the GNPS center is currently constituted into six major groups. These are the Nuclear Fuel and Materials (NFM) group, Advanced Instrumentation and Control (AIC) group, Innovative Cooling Enhancement (ICE) group, Experimental Support (ES) group, System Code Development (SCD) group, and Education and Training (ET) group. Each of these six groups, which strongly interacts and collaborates among one another, focuses on the following state-of-the-art research, education and training activities to develop specific marketable tools and products:

- NFM Group: The initial focus of this group is on materials research for enhanced cooling and heat transfer (micro-porous coating materials for enhanced cooling, sacrificial and refractory materials for in-vessel and ex-vessel core catchers, etc.). Later efforts will address nuclear fuel cycles as well as nuclear fuel and material issues in operation and storage. Marketable research products include special materials suitable for cooling enhancement, nuclear fuel and materials property data, performance data, and irradiation data.

- AIC Group: This group focuses on the development of control algorithms for accident managements, advanced sensors for in-situ diagnostics of molten core materials (such as high-heat-flux gauges, molten corium sensors, etc.), and advanced instrumentation for experimental measurements under high-temperature, high-pressure conditions typical of those anticipated under DBA and BDBA conditions in nuclear reactors. Marketable research products include advanced instrumentation, advanced sensors, and control algorithms.

- ICE Group: This group focuses on the development of innovative cooling enhancement (ICE) techniques for cooling of commercial-size high-power reactors under both DBA and BDBA conditions so as to enhance their thermal margins for safety performance required for licensing of these advanced reactors. Marketable research tools and products include ICE concepts and technologies, ICE data, and specific ICE devices.

- ES Group: This group focuses on the design and development of various test facilities that can be utilized to conduct targeted experiments under simulated DBA and BDBA conditions. Advanced instrumentation developed by the AIC group is employed in these test facilities to obtain comprehensive sets of experimental data that can be used for model development and code validation. Marketable research tools and products include NP safety test facilities and base technology data.

- SCD Group: This group focuses on the development and upgrading of transient system analysis codes that can be used to predict the thermal hydraulics response of a nuclear reactor under accident conditions. Physics-based models are being developed utilizing the NP safety data obtained by the ES group and the newly developed models will be implemented in the codes to enhance its capability in more realistically predicting the thermal hydraulics response. Marketable research tools and products include stand-alone as well as upgraded system analysis codes for reactor thermal hydraulics and safety analysis, verification and validation, and benchmarking data.

- ET Group: This group focuses on creating opportunities for outreach, education, and training along with the development of educational and training tools, utilizing the various research tools and products generated by the other five groups at the Center to prepare technical documents, training materials, course materials, and other relevant information. Marketable educational tools and products include technical reports, dissertations, theses, papers, thermal hydraulics and safety workshops, short courses, distance learning courses, seminars, and summer schools. These educational tools and products will be utilized not only to educate and train professional engineers, practitioners, designers, researchers, and multidisciplinary students in the NP safety area, but also serve as a vehicle to advertise the technical capabilities of the Center for attracting funding from research sponsors.

Strengths

Some of the research tools and products have already been developed by the Center faculty at Penn State and utilized in various externally funded NP research projects. Specifically, the following research tools involving five NP safety test facilities have been built and are currently in operation:

- Rod Bundle Heat Transfer (RBHT) Test Facility

- Advanced Multiphase Flow Laboratory (AMFL)

- Minimum Film Boiling Temperature (TMIN) Test Facility

- Subscale Boundary Layer Boiling (SBLB) Test Facility

- Cold Spray (CS) Test Facility

The first four facilities were developed under the sponsorship of the NRC (with the second facility, i.e., AMFL, also co-sponsored by DOE and Bettis) whereas the last one was developed under the sponsorship of Navy. The first three facilities are currently being used to investigate the thermal hydraulics phenomena and mechanisms during design basis accidents whereas the last two facilities are being used to study the thermal hydraulics phenomena and mechanisms during in-vessel cooling of nuclear reactors under severe accident conditions. High-quality comprehensive sets of data, most of which not available in the literature or to the public, have been gathered from these facilities. These sets of data are currently being utilized for model development and code validation. In addition to data, advanced instrumentations and innovative cooling enhancement (ICE) concepts and techniques have also been developed that can readily be used in commercial-size nuclear reactors under high-temperature high-pressure accident conditions.

Another significant research product currently available at PSU is an improved version of a transient system analysis code, COBRA-TF (Coolant Boiling in Rod Arrays – Two Fluids). It is a thermal hydraulics simulation code designed specifically for light water reactor (LWR) vessel analysis under design basis accident conditions. The code was originally developed by Pacific Northwest Laboratory in 1980 and had been used and modified by several institutions including Westinghouse over the last three decades. The improved version of COBRA-TF available at PSU has enhanced numeric capability and is a version most widely used by NP safety researchers and practitioners in the US and abroad. The NRC also uses this version as a reference for comparison with the NRC’s own system analysis code, TRACE. The latter is being used by the NRC for licensing of nuclear reactors. An important consideration during the licensing review process is the margin-to-core-uncover and how the core behaves when cooled by a two-phase mixture of steam and water. Existing models for two-phase heat transfer have high uncertainties, not only in COBRA-TF but also in TRACE. To eliminate or minimize these uncertainties, the NRC is currently sponsoring key participants of the Center at PSU with the total amount of $3M for five years (2012-2017) to obtain new high-temperature, high-pressure data from the RBHT Test Facility for the development of new/improved two-phase heat transfer models for implementation to TRACE. The Center is currently utilizing the new data and new/improved models to develop a stand-alone computational program readily to be implemented in an upgraded version of COBRA-TF as well as TRACE that can more realistically predict the thermal hydraulics behavior of a rod bundle and the cooling of a nuclear reactor under DBA conditions.

On the education side, Penn State has one of the strongest nuclear engineering distance-learning programs not only in the U.S. but also worldwide. The nuclear engineering resident undergraduate and graduate program have strong international participation with students from United Arab Emirates, Kazakhstan, China, France, Spain, South Africa, United Arab Emirates, Bulgaria, Korea, Turkey, Kuwait, etc. Recently nuclear engineering global teams have been established with SJTU and XJTU in China and KTH in Sweden. Individual NP faculty members have conducted numerous short courses and workshops in the NP safety area in many countries. The Center will provide an excellent environment for nurturing and training multidisciplinary undergraduate and graduate students who are interested in becoming the future industry and academic leaders in the global NP safety area.

Center Membership

- Silver Members: This membership will require a minimum contribution of $25,000/year. A silver member is entitled to use one of the marketable research products of the Center and will receive technical support from the Center on using the selected product.

- Gold Members: This membership will require a minimum contribution of $ 100,000/year. A gold member is entitled to use more than one marketable research product of the Center and will receive technical support from the Center on using the selected products. In addition, a gold member may choose to work with the Center faculty utilizing the resources of the Center including the test facilities and/or the system analysis codes on modifying a particular marketable research product of the Center to fit specific needs of the member. Depending on the type of modifications requested by the member, multi-year MOU agreements may need to be signed.

Marketable research products include special materials suitable for cooling enhancement, material property data, performance data, irradiation data, advanced instrumentation, advanced sensors, control algorithms, ICE concepts and technologies, ICE data, specific ICE devices, NP safety test facilities and base technology data (except NRC-owned RBHT data), stand-alone as well as upgraded system analysis codes for reactor thermal hydraulics and safety analysis, benchmarking data, technical reports, and dissertations.